Available Pot Sizes:

Colour Oil is available in the container sizes of 1 and

2,5 litre containers and in the colours light brown,

brazil brown, red brown, tea-chest brown, rhode Island brown, walnut, castle grey, extra grey, extra white and black.

Tools:

A polishing machine with beige polishing pad. Paintroller and cotton cloths. Clean tools in Solvent.

How to do...

Suitable for oak, ash, spruce, larch, pine and teak,

as well as cork. The oil brings out the natural wood grain and gives a hard-wearing surface, which is easy

to maintain.

In order to obtain a uniform result, it is recommended to prime beech, spruce and pine wood with Maintenance Oil. After application, leave to dry for approx. 1 hour.

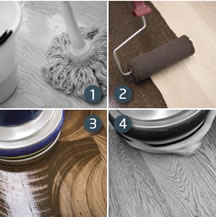

1. The floor or woodwork should be freshly sanded and completely clean, dry, and free from stains before the application of the Colour Oil. Clean with 125 ml Wood Cleaner mixed with 5 l water.

2. Shake the container with Colour Oil well before and during application. Apply the oil in an even coat onto an area of approx. 15 m2 with a short-haired paintroller. Let the floor absorb the oil for approx. 20 min. Subsequently, the oil is worked into the wood with a beige polishing pad either manually or for large areas with a floor machine. Polish for approx. 15 min. or until the floor appears saturated with oil.

3. Beware! Should any excess oil appear on the surface, remove this with cloths or paper or scrape onto next section of floor to be oiled. Buff floor with white polishing pads and with lint-free cotton cloths under the floor machine.

4. The colour oiled floor is pre-hardened after approx. 6 hours at room temperature of 20° C and completely hardened after 72 hours. If a higher saturated surface is required, the finished floor may be buffed with 100 ml of Colour Oil to 10m2 of floor. This is done after the pre-hardening time and the oil must

be polished carefully into the floor. Cover walking areas with corrugated cardboard for 72 hours. Do not expose the floor to water during the hardening time.

Please notice:

Risk of self-ignition! Due to the risk of self-ignition it is important that sanding dust and oil wetted cloths are soaked in water and disposed of in a tightly closed container after use.

Seiten zum weitersurfen: unsere Webtipps

weiterführende Seiten zum Thema Laugen von Holz: Verarbeitung Trip Trap Lauge

Diese Webseite ist urheberrechtlich geschützt. Unerlaubte Verwendung wird verfolgt.

© by info-art agentur für kommunikation